Village Rainbows

My life has taken me down many different paths, each with its own blessing. This is my way of sharing some of those paths.

This blog site was started at a time when I was living Ghana, West Africa. I wrote about topics which were of interest or concern to me at the time. In one example, as a member of the Edubiase Traditional Council, I took part in the celebration of the Asantehene’s (King of Ashanti people) anniversary.

As another example, there was a post about my farming attempts in Ghana.

In more recent times, the blog has focused on my activities in Canada, including boat building. This post told the story of sewing up a sail for my sailboat.

I do hope you will feel like exploring some of my old posts, and while you are at it, leave your comments.

New paths

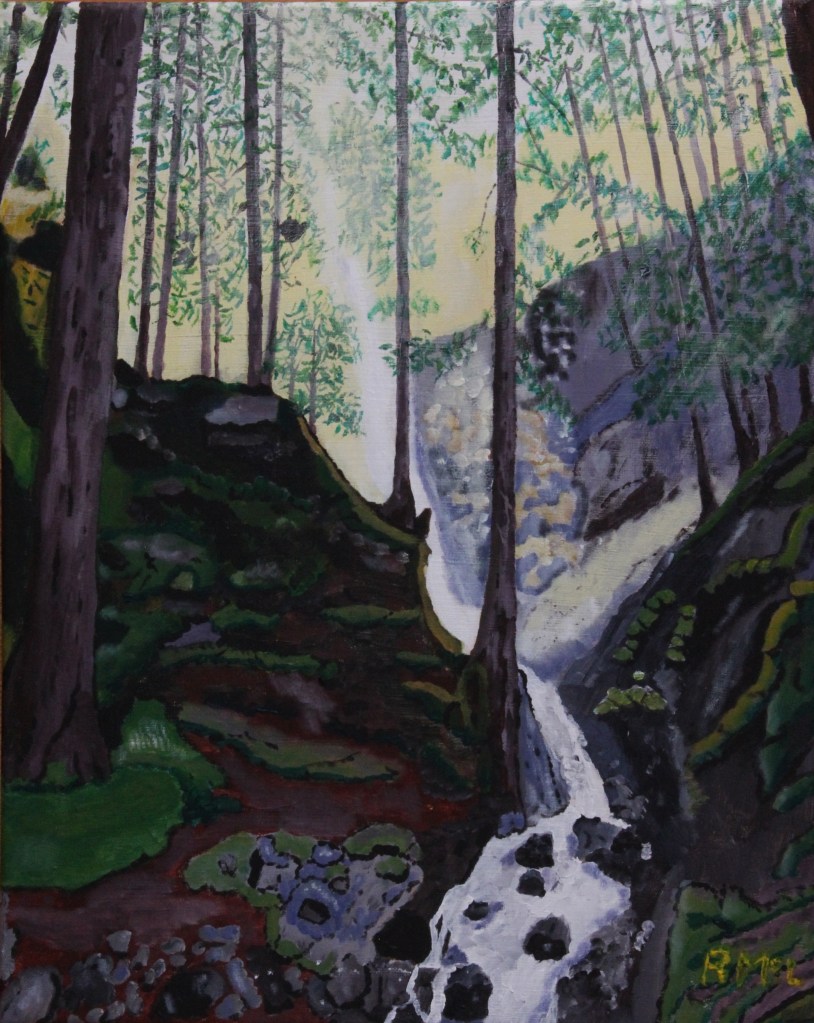

In 2014 during an unusual (for me) winter holiday in Arizona, I decided to play around with paints and brushes. The first efforts were rather crude, as you can see. But with instructions and encouragement from my partner, things slowly improved. In recent years, i have taken part in the Open Studio classes which are offered by Hues Art Supply. Instructor Degen Lindner has encouraged me to “loosen up” and with her urging, my painting has moved to new levels. I paint primarily from my personal experience most often using for inspiration photos which I have taken .

If you enjoy paintings, or if you are painting yourself, I invite you to follow my work in the gallery section.

If you would like to know the next time new posts are published or new paintings are added, be sure to hit the “SUBSCRIBE” button.

I welcome comments and questions. A comment page has been set up so we can begin a conversation.

Cheers, Rod McLaren